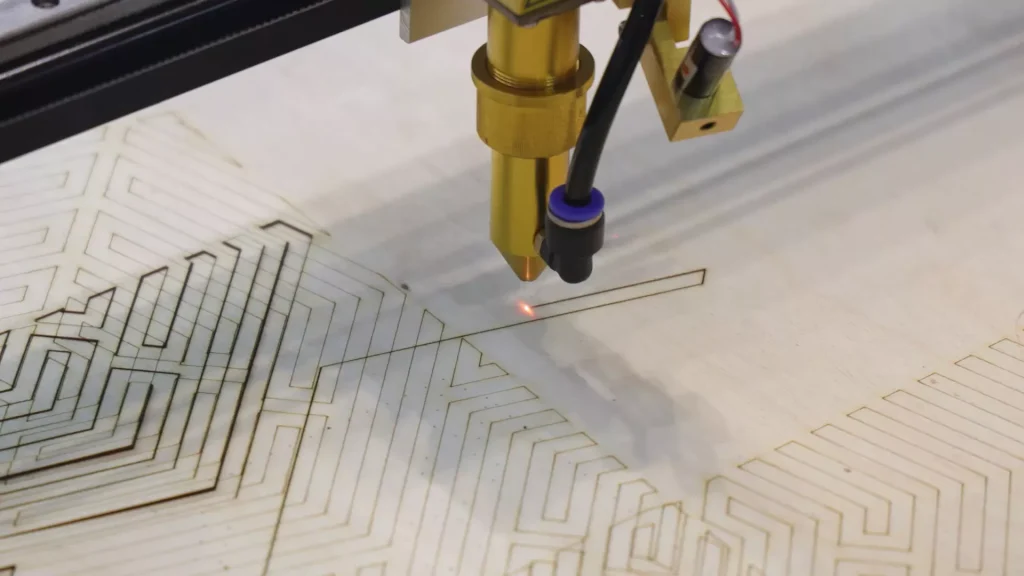

CNC laser cutting

Service Plast is a modern company specializing in precise material processing using advanced CNC laser cutting technology, focusing mainly on plastics such as plexiglass (PMMA). Thanks to the use of high-precision lasers, the company can carry out complex projects maintaining impeccable cutting quality, which is particularly important for projects requiring the highest accuracy and quality of finish.

Our advantages:

Perfectly transparent edges: One of the biggest advantages of laser cutting in plexiglass is the ability to achieve perfectly smooth and transparent edges without the need for additional processing. This makes the material ideal for applications where aesthetics and precision are paramount, such as in display, advertising, or designer components.

Complex shapes and details: Laser technology allows for the creation of complex shapes and patterns that would be difficult or impossible to achieve using traditional processing methods. The precision of CNC laser cutting enables the realization of even the most intricate projects according to the customer's requirements.

Bending after cutting: Elements produced using laser cutting can subsequently be formed on bending machines, opening up additional design and construction possibilities. Service Plast offers comprehensive services that include both cutting and bending of plastics, providing customers with ready-to-use components of high quality and aesthetics.

High efficiency and fast execution: Laser cutting is an extremely efficient process, allowing for the speedy completion of even large orders. Service Plast, through the use of the latest laser technology, can guarantee short delivery times while maintaining high product quality.

Technical and project support: The company not only fulfills orders according to ready-made projects provided by customers but also offers support during the design phase. Thanks to experience and technical knowledge, Service Plast can assist in optimizing projects for technological and economic efficiency, which is particularly valuable for complex or innovative ventures.

Applications:

Laser cutting services offered by Service Plast are widely used in various industries and projects, from advertising to design to industry and construction. They are ideal for the production of signs and spatial letters, decorative elements, furniture components, machine covers, or other specialized parts requiring precise cutting and elegant finishing.

Thanks to the use of CNC lasers, the company can execute the most demanding projects, offering products with high precision and aesthetics.

Extended cutting capabilities:

Cardboard: Laser cutting allows for precise cutting of details from cardboard, which is especially useful in the production of packaging, decorative elements, architectural models, or prototypes. Precise cutting ensures clean edges and the ability to realize complex patterns.

Plywood: Plywood is a popular material in many industries due to its durability and flexibility. Laser cutting enables the creation of precise components for furniture, toys, display and decorative elements, and other projects requiring precision and aesthetics.

Rubber: Laser cutting of rubber opens up new possibilities in the production of gaskets, mats, cushioning elements, and other rubber parts where high cutting precision is required. Laser technology allows for the quick and efficient cutting of complex shapes without the need for traditional forms and tools.

Advantages of laser cutting at Service Plast:

- Versatility: The ability to work with various materials opens up a wide range of applications and projects for Service Plast customers.

- Precision: The laser ensures unparalleled cutting accuracy, which is crucial in executing details with complex shapes and patterns.

- High-quality finish: Laser cutting minimizes the risk of material damage, offering clean and smooth edges without the need for additional processing.

- Speed and efficiency: The laser cutting process is significantly faster compared to traditional methods, resulting in shorter project delivery times.

Thanks to flexibility in handling various materials and a commitment to delivering high-quality services, Service Plast is able to meet the needs of a wide range of customers seeking professional solutions in material processing. The company continually strives to improve its skills and technology to ensure the highest standard of execution in every project.