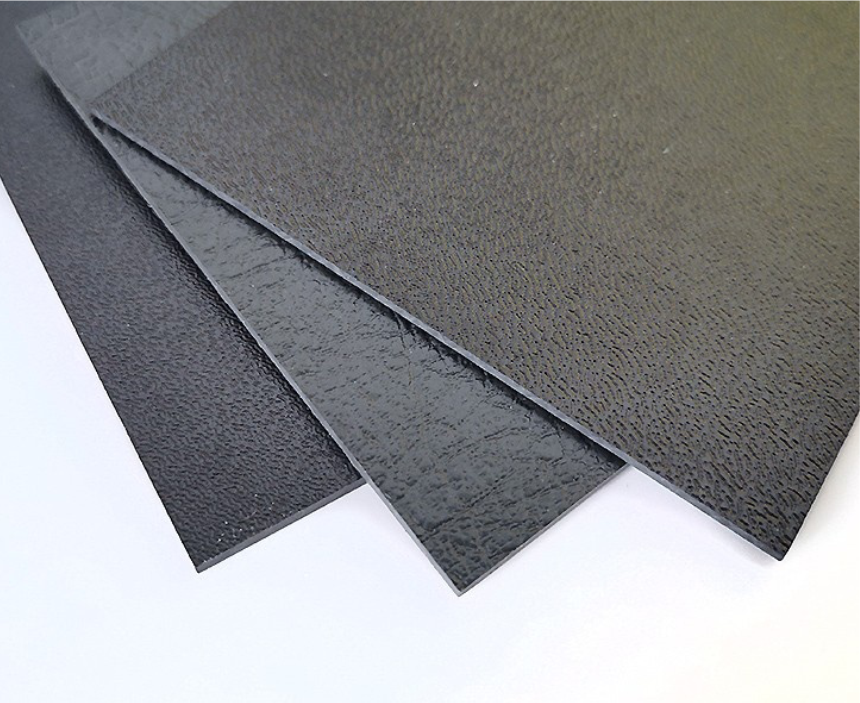

ABS plates

ABS Sheets

ABS sheets (acrylonitrile-butadiene-styrene) are a thermoplastic polymer that, thanks to its unique properties, finds widespread application in many industries. It is a material known for its good combination of rigidity, impact resistance, and chemical and scratch resistance.

Properties of ABS Sheets:

- Impact Resistance: ABS is known for its high impact resistance, making it ideal for the production of components that need to withstand intensive use.

- Ease of Processing: This material can be easily cut, drilled, milled, and bent after preheating, which allows for the creation of complex shapes and details.

- Good Resistance to Temperature and Chemicals: ABS is characterized by stability across a wide range of temperatures and resistance to many acids, bases, and other chemical substances.

- Aesthetic Properties: The flat, smooth surfaces of ABS sheets can be easily painted, lacquered, or printed on, allowing for extensive decorative possibilities.

Applications of ABS Sheets:

- Automotive Industry: Interior and exterior vehicle elements, such as dashboard panels, mirror housings, and other components.

- Housings for Electronic and Household Appliances: Due to its properties and aesthetics, ABS is often chosen as the material for housings of phones, computers, printers, and small and large household appliances.

- Consumer Products: Toys, sports equipment, interior fittings, and packaging.

Availability:

We offer ABS sheets in the following thicknesses:

- 1mm

- 2mm

- 3mm

- 4mm

Sheet Sizes:

- 1000x2000mm

- 2000x3000mm

Processing Methods:

- Cutting and Milling: ABS sheets can be easily cut and milled, allowing for precise shaping of the material.

- Thermoforming: This material is well-suited for thermoforming, which involves shaping by heating, allowing for the creation of complex three-dimensional shapes.

- Welding and Gluing: ABS can be effectively welded and glued with special adhesives, enabling the creation of larger structures and joining elements.

- ABS sheets are a versatile material that, thanks to its combination of strength, ease of processing, and aesthetic possibilities, finds application in a wide range of products and projects. Its popularity among designers and engineers stems from its good physical and mechanical properties as well as flexibility in design and production.