About Us

A company founded in 2020, which quickly gained a reputation as a trusted supplier of high-quality plastics and innovative CNC processing solutions. Our company is growing dynamically, with a focus on excellent service quality.

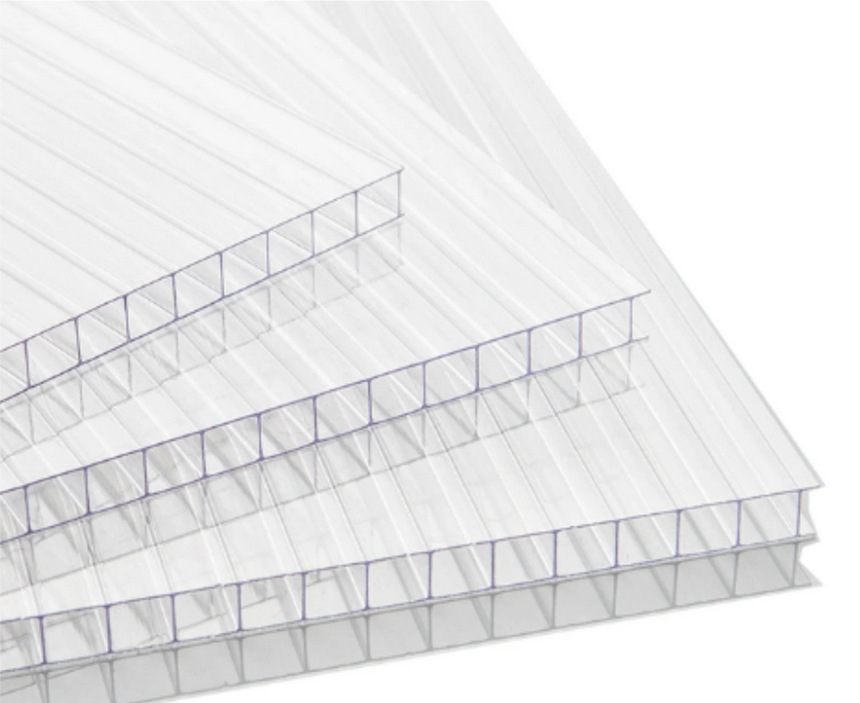

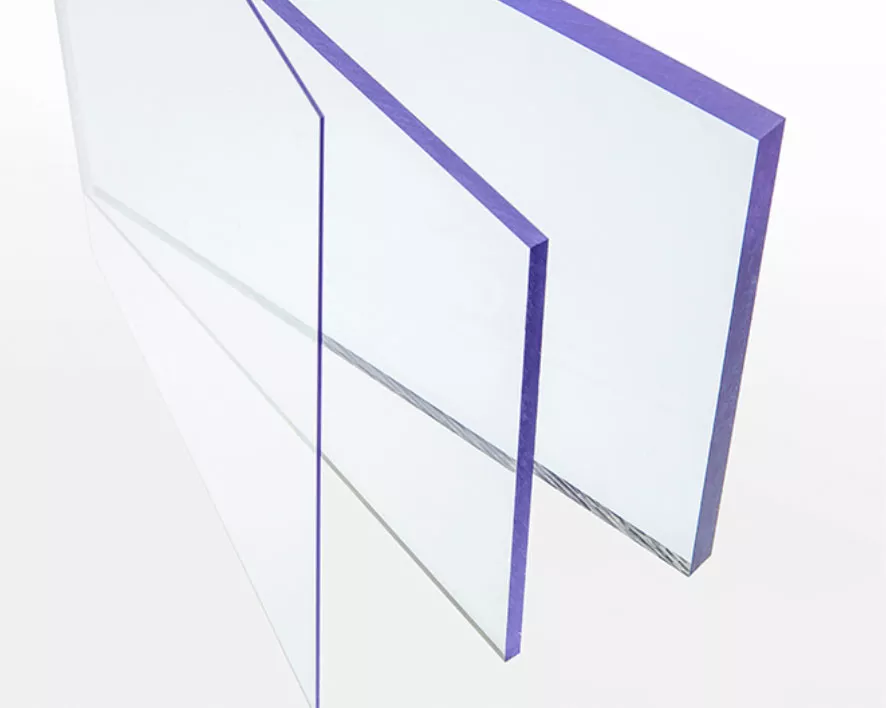

We specialize in offering a wide range of plastics, including materials for canopies made of polycarbonate, both cellular and solid.

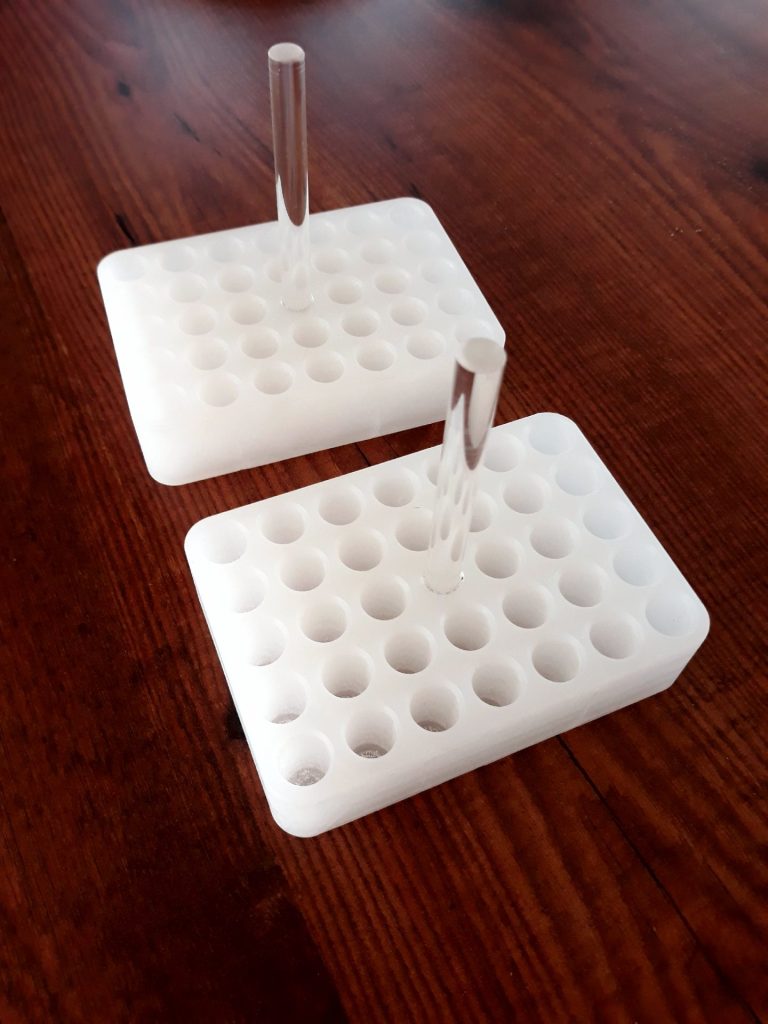

We supply companies and individual customers with materials such as:

- Plexiglass/Acrylic glass (PMMA)

- Solid polycarbonate (PC)

- Cellular polycarbonate

- High-density polyethylene (PEHD)

- Composite panels (HPL)

- Foamed PVC panels

- ABS panels

- HIPS panels

- Aluminum composite panels (Dibond)

Highest Quality

Thanks to the high quality of products offered and professional service, Service Plast enjoys the trust of many clients from various industries, both domestic and international. The company continuously develops, keeping up with the latest trends and technologies in its field, which allows us to deliver the best solutions for every order.

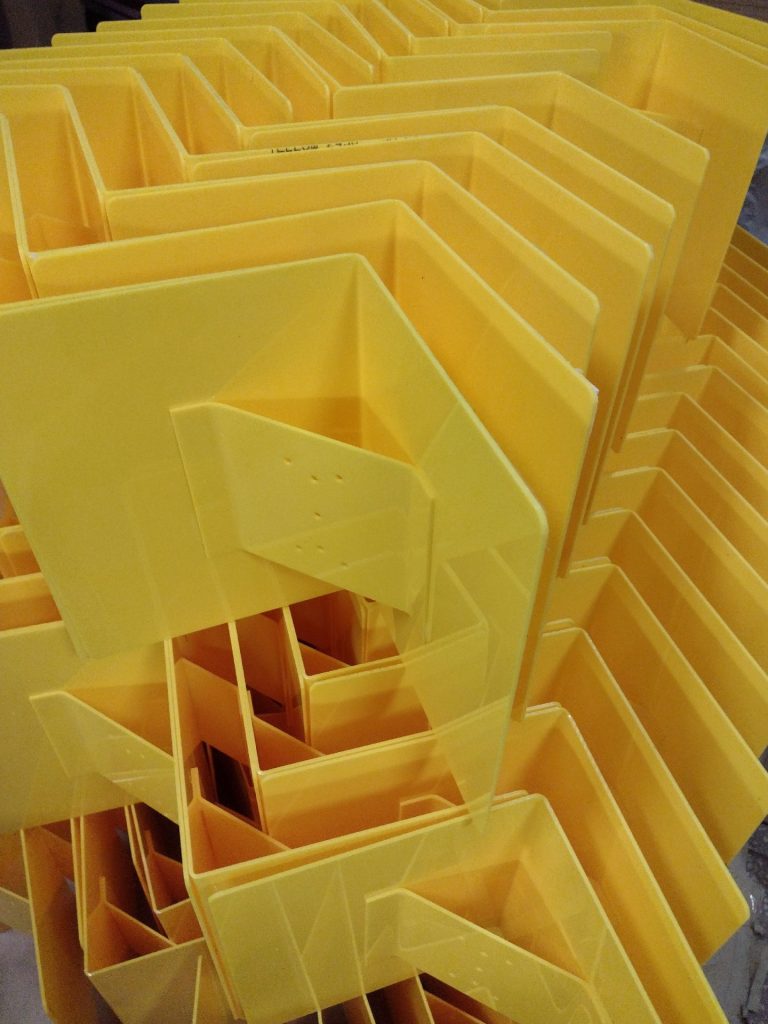

Our company offers comprehensive services in the field of CNC milling, laser cutting of plastics, bonding, and bending plastics. With our experience and modern machinery, we can complete any order, regardless of its scale or complexity.

We collaborate with companies from various sectors, such as the furniture industry, refrigeration, advertising, and construction. As a result, we have earned the trust of customers throughout Poland who value our quality and timely order fulfillment.

At Service Plast, we care about our clients and their needs, which is why we also offer custom-designed projects and the option of choosing individual solutions tailored to specific requirements. Our team of experienced specialists also provides expert advice and assistance in selecting the right material and technology.

We invite you to contact us and take advantage of our services! We guarantee the highest quality of workmanship, competitive prices, and full satisfaction with our cooperation.

Machinery Park

Our machinery park allows us to deliver products with excellent quality and serial reproducibility.

Multicam 5000 Milling Machine - CNC Center with a working range of 4300 x 2150 mm

From prototyping to full production runs. Our 3-axis milling center will allow you to produce very precise and high-quality components.

The MultiCam 5000 series is a highly advanced line of CNC machines designed for heavy industrial applications, offering exceptional speed, precision, and durability. It is a solution aimed at companies requiring maximum efficiency and reliability in processing a wide range of materials, including metals, plastics and composites. It finds application in industries such as aviation, automotive, sign and advertising production, as well as woodworking and furniture manufacturing.

Main features and advantages of the MultiCam 5000 machine:

- High performance: Thanks to the use of advanced technological solutions, the machine ensures high cutting speeds while maintaining precise dimensions and processing quality.

- Advanced technology: MultiCam 5000 utilizes the latest control and drive technologies, resulting in exceptional accuracy and cut repeatability.

- Robust construction: Designed for heavy-duty operation in tough industrial conditions, guaranteeing long lifespan and minimal maintenance requirements.

- Versatility: The 5000 series can efficiently process a variety of materials, making it an ideal solution.

- Intuitive operation: The control system is easy to use, minimizing the need for lengthy operator training and allowing for quick onboarding of new staff.

- Customization: MultiCam offers wide configuration possibilities of the machine, allowing it to be tailored to specific production needs, including various tooling and automation systems.

The MultiCam 5000 machine can meet the most demanding machining tasks in heavy industrial environments.

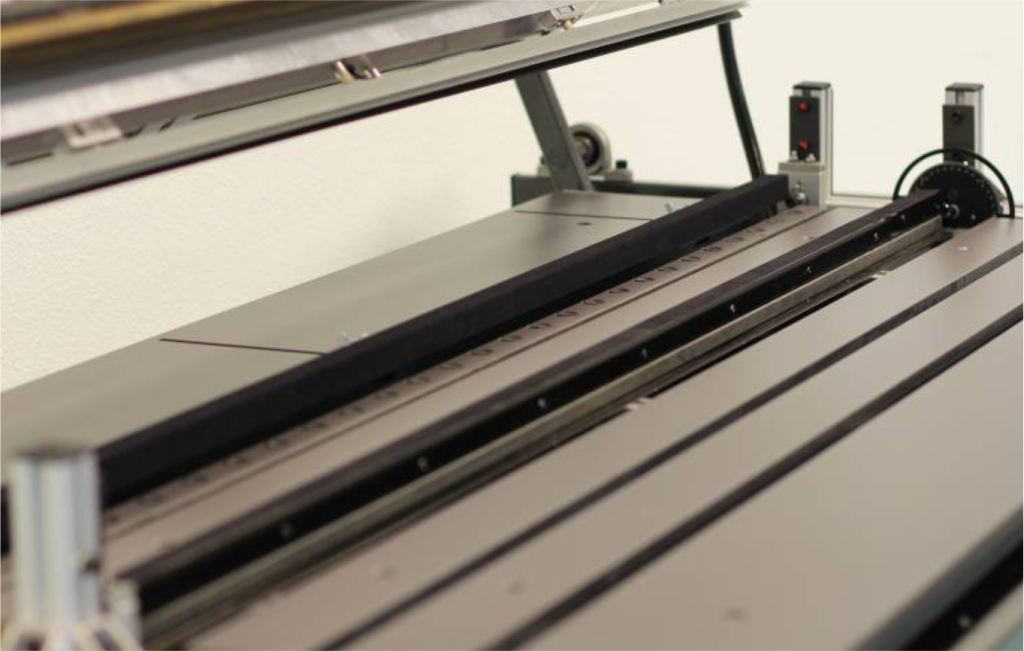

Multicam 3000 Milling Machine - CNC Center with a working range of 4300 x 2150 mm

The MultiCam 3000 milling plotter is an advanced CNC milling system designed for the precise processing of a wide range of materials, from metals to plastics and wood. It is characterized by high build quality, reliability, and application flexibility, making it a popular choice in the manufacturing industry, advertising, and artisanal workshops.

Advantages of the MultiCam 3000 machine:

- Versatility: Capable of processing various materials, making it ideal for companies involved in diverse production activities.

- Precision: Provides very high cutting accuracy, crucial in many industrial and artistic applications.

- Automation: The ability to program and automate cutting processes significantly increases work efficiency while minimizing the risk of errors.

- Time savings: The speed and efficiency of cutting shorten production time, which is important in a rapidly changing production environment.

- Ease of use: Intuitive user interface and available technical support facilitate quick operator training and minimize downtime.

- Reliability: Durable construction and use of high-quality components ensure a long machine life and low maintenance costs.

Thanks to these advantages, the MultiCam 3000 machine is valued by users who require reliable, precise, and flexible CNC technology for their projects.

Multicam 3000 Milling Machine - CNC Center with a working range of 3150 x 2150 mm

The MultiCam 3000 machine is an advanced CNC milling system designed for the precise processing of a wide range of materials, from metals to plastics and wood. It is characterized by high build quality, reliability, and application flexibility, making it a popular choice in the manufacturing industry, advertising, and artisanal workshops.

Advantages of the MultiCam 3000 machine:

- Versatility: Capable of processing various materials, making it ideal for companies involved in diverse production activities.

- Precision: Provides very high cutting accuracy, crucial in many industrial and artistic applications.

- Automation: The ability to program and automate cutting processes significantly increases work efficiency while minimizing the risk of errors.

- Time savings: The speed and efficiency of cutting shorten production time, which is important in a rapidly changing production environment.

- Ease of use: Intuitive user interface and available technical support facilitate quick operator training and minimize downtime.

- Reliability: Durable construction and use of high-quality components ensure a long machine life and low maintenance costs.

Thanks to these advantages, the MultiCam 3000 machine is valued by users who require reliable, precise, and flexible CNC technology for their projects.

CNC Laser Plotter with a working range of 2600 x 1600 mm

A CO2 laser with a working area of 2600x1600 mm is a versatile tool for cutting and engraving a wide range of materials, including a wide range of plastics. Its unique properties make it extremely useful in many industries, from industrial production to design and art. Here are the key benefits of using a CO2 laser for processing plastics:

- Cutting and engraving precision: The CO2 laser offers exceptional processing accuracy, allowing the creation of complex designs and delicate details without the risk of damaging the material.

- High edge quality: The laser cutting process minimizes the need for further edge processing, as the laser melts the plastic, leaving smooth and clean edges without fraying or roughness, which is typical for mechanical methods.

- Versatility: The large working area of the laser allows the processing of large sheets of material, which is ideal for large-scale production and allows for the implementation of larger projects without the need for dividing them into smaller parts.

- No material contact required: Laser processing is a non-contact method, which means there is no risk of damaging delicate materials by pressure or friction. This also eliminates tool wear and the need for their replacement.

- Ability to cut various materials: In addition to plastics, the CO2 laser can be used to cut and engrave wood, glass, paper, leather, and many other materials, making it a versatile tool in production.

- Speed and efficiency: CO2 lasers can process materials quickly and with minimal waste, which translates into increased production efficiency and cost reduction.

- Automation and repeatability: Laser systems can be easily integrated with CAD/CAM software, enabling process automation and ensuring high repeatability of results, even in large production runs.

Thanks to these benefits, a CO2 laser with a large working area is a valued tool in industries requiring precise, fast, and efficient processing of plastics, offering flexibility and high-quality workmanship.

CNC Thermal Plotter with a working range of 1200 x 600 x 600 mm

Thanks to advanced technology and precision manufacturing, this plotter significantly extends our production capabilities, offering customers cutting services at the highest level.

Main features and advantages of our CNC thermal plotter:

- Exact cutting: Our CNC plotter uses advanced thermal cutting technology, which allows for very precise cutting of styrodur and styrofoam, without the risk of damaging the material. This is an ideal solution for demanding projects where precision is key.

- High efficiency: Automation of the cutting process significantly increases production efficiency, enabling large orders to be fulfilled in a short time. As a result, we can meet even the most demanding delivery deadlines.

- Versatility: The plotter is adapted to work with various thicknesses and densities of styrodur and styrofoam, allowing for a wide range of applications in different projects—from simple decorative elements to complex structural components.

- Software: Using professional CAD/CAM software enables fast design and modification of projects, significantly reducing the time from concept to the realization of the finished product.

Wichary GT2040 Thermal Bender

is an advanced device designed for precise bending of plastics and other thermoplastic materials. Designed with high efficiency and ease of use in mind, it finds wide application in various industries—from advertising to automotive and aerospace. Thanks to its design and the use of modern technologies, this bender allows for complex bends while maintaining high precision and quality of the final product.

Key features and advantages of the Wichary GT2040 thermal bender:

- Versatility: The bender can handle a wide range of thermoplastic materials, including PVC, PET, polycarbonate, acrylic, plexi, and many others, making it an extremely versatile tool in the production of plastic components.

- Bending precision: Thanks to precise temperature control and even distribution, the device ensures excellent bending quality, minimizing the risk of cracking or material distortion.

- Ease of use: The Wichary 2000 bender was designed for ease of use. An intuitive control panel and the ability to program different work modes significantly simplify the bending process, even for less experienced operators.

- High work efficiency: The device is characterized by fast heating time and the ability to simultaneously bend multiple elements, which translates into increased production efficiency.

- Solid construction: The device features a durable and stable construction, ensuring long-term reliable operation even in demanding industrial conditions.

Automatic Thermal Bender

The automatic bender for plastics, with a maximum bending width of 145 cm and the ability to process materials up to 20 mm thick, is an innovative device dedicated to working with a wide range of plastics. Thanks to the use of advanced technology and precise control systems, this machine is capable of carrying out complex bending tasks with high accuracy and repeatability.

Key features of the device:

- Versatility: The bender is adapted to work with various types of materials like acrylic, polycarbonate, PETG, and many others, making it an ideal solution for different industry sectors, from advertising to construction.

- Precision: The use of precise control mechanisms and uniform heat distribution guarantees perfect bends without the risk of cracking or distortion, even at maximum material thickness.

- Automation: Full automation of the bending process significantly increases production efficiency, minimizes operator intervention, and allows for quick execution of complex orders.

- Speed and efficiency: Thanks to fast heating times and the ability to bend multiple elements simultaneously, this machine ensures exceptional productivity, leading to shorter production cycles and lower operating costs.

- Ease of use and maintenance: An intuitive user interface and minimal maintenance requirements make the bender user-friendly for operators and easy to maintain.

Frequently asked questions:

What services does Service Plast provide?

We offer services in the field of plastic processing, including laser cutting, CNC milling, plastic bonding, bending, and the execution of custom interior design projects.

Does Service Plast offer accessories for installing multiwall polycarbonate?

Yes, we provide our customers with all the necessary accessories for installing multiwall polycarbonate sheets. Our range includes gaskets, polycarbonate and aluminum profiles, tapes, and washers.

Does Service Plast carry out single and custom projects?

Yes, we carry out projects according to individual customer requirements.

What are the maximum dimensions of materials that Service Plast can process?

The maximum dimensions depend on the specific material; however, they generally do not exceed 4 x 2 m.

Does Service Plast offer delivery of ordered products?

Yes, we offer delivery throughout the entire country.

What payment methods does Service Plast accept?

We accept cash payments and bank transfers.

Does Service Plast offer discounts for regular customers?

Yes, we offer discounts for regular customers as well as for customers placing larger orders.

Does Service Plast guarantee the quality of its products?

Yes, we guarantee high quality of our products and full customer satisfaction.